Premier Aluminum Llc for Dummies

Wiki Article

Some Known Details About Premier Aluminum Llc

Table of Contents5 Easy Facts About Premier Aluminum Llc DescribedWhat Does Premier Aluminum Llc Do?All About Premier Aluminum LlcSome Of Premier Aluminum Llc

(https://www.avitop.com/cs/members/premieraluminum.aspx)

Typically, a purchaser's main duty was to discover professional and responsive providers. Sometimes, buyers thought that any kind of provider ready to contractually satisfy the acquisition requirement was qualified. Nevertheless, making use of affordable and unqualified vendors can create high quality issues, and lost time and money in the future. To assist you with the process, here are some points to consider when picking the best metal spreading distributor.

As an example, a firm that only uses the financial investment casting procedure will certainly try to market you on why that process is best for your application. What if utilizing the sand spreading process is best for you and your demands? Instead, try to find a supplier that provides a variety of casting procedures so the best alternative for YOU is picked

If collaborating with a solitary source for every one of your spreading needs is very important to you, the distributor needs to be varied in its capacities. When incorporated with various other incorporated capacities, this can aid streamline and compress the supply base. When selecting the best spreading provider, cautious factor to consider must be offered to quality, solution, and cost.

Premier Aluminum Llc Fundamentals Explained

Buyers progressively pick spreading providers who have machining capacities. This can avoid dispute if defects are found throughout machining. If a 3rd party is machining, it may lead to "finger-pointing" concerning that is at mistake. Is it a spreading issue or a machining issue? If the spreading vendor uncovers a problem throughout machining, the issue is dealt with quicker without conflict over whose fault it is.What do you original site require from your casting vendor? Are you looking for someone to simply provide a metal component to your front door or do you require a lot more?

Some factories are limited or specialized. Make sure the supplier can satisfy all your product or alloy needs to eliminate the requirement for numerous suppliers.

Our Premier Aluminum Llc Diaries

Research the provider's site. Talk to a sales rep or service associate.

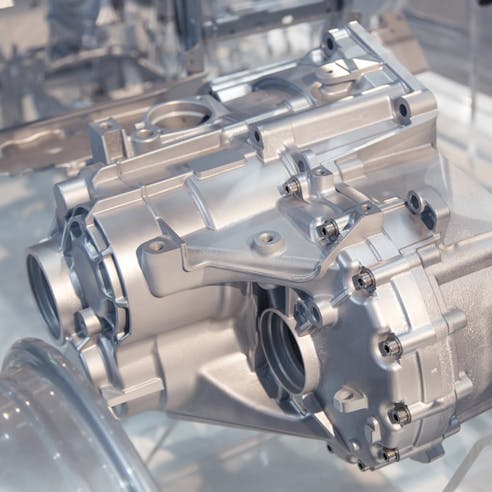

Light weight aluminum is additionally light-weight and has good deterioration resistance, making it excellent for applications where weight and resilience are vital variables. Additionally, aluminum spreading is a cost-efficient approach of production, as it calls for less energy and sources than other techniques. Iron spreading, on the various other hand, entails pouring molten iron into a mold to create a desired form.

The 6-Minute Rule for Premier Aluminum Llc

Iron casting is likewise able to endure high temperature levels, making it appropriate for usage in applications such as engine parts and industrial equipment. However, iron spreading can be a lot more expensive than light weight aluminum casting due to the greater cost of raw materials and the power needed to melt the iron. When making a decision between aluminum casting and iron spreading, it is necessary to think about the specific requirements of the application.In final thought, both aluminum casting and iron spreading have their very own unique benefits and negative aspects. There are 3 sub-processes that drop under the category of die spreading: gravity pass away spreading (or long-term mold casting), low-pressure die spreading and high-pressure die casting. To obtain to the completed product, there are 3 main alloys used as die casting product to pick from: zinc, aluminum and magnesium. Report this wiki page